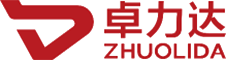

Comfortable shaving

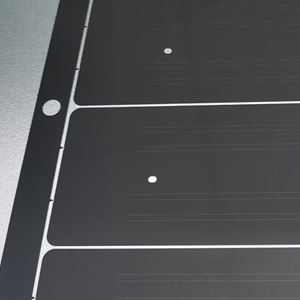

High precision mesh holes and smooth surfaces can reduce friction and irritation to the skin, providing a more comfortable shaving experience.

durability

Electroformed shaver nets often have high strength, corrosion resistance, and long service life.

Design flexibility

Electroforming technology can achieve complex designs and structures, meeting the personalized needs of different brands and products.

Cost effectiveness

Although the initial cost of electroplating process is high, it has good cost-effectiveness in mass production, especially for high-end products.

High end shaver

Electroformed shaver mesh is commonly used in high-end manual shaver products, providing an excellent shaving experience.

For example, some high-end brands of rotary and reciprocating razors use electroplated mesh.

Customized products

Electroforming technology can achieve customized design to meet the special needs of different customers and markets.

Electroformed shaver mesh combines the precision manufacturing advantages of electroplating technology with the functional requirements of shaver mesh, and has the advantages of high precision, complex structure, high surface smoothness, and durability. The shaver net manufactured through electroplating technology can provide excellent shaving experience and is widely used in high-end shaver products.

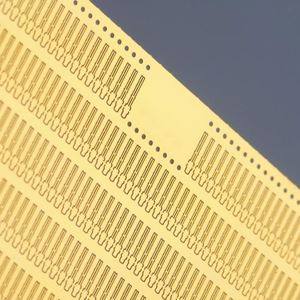

high-precision

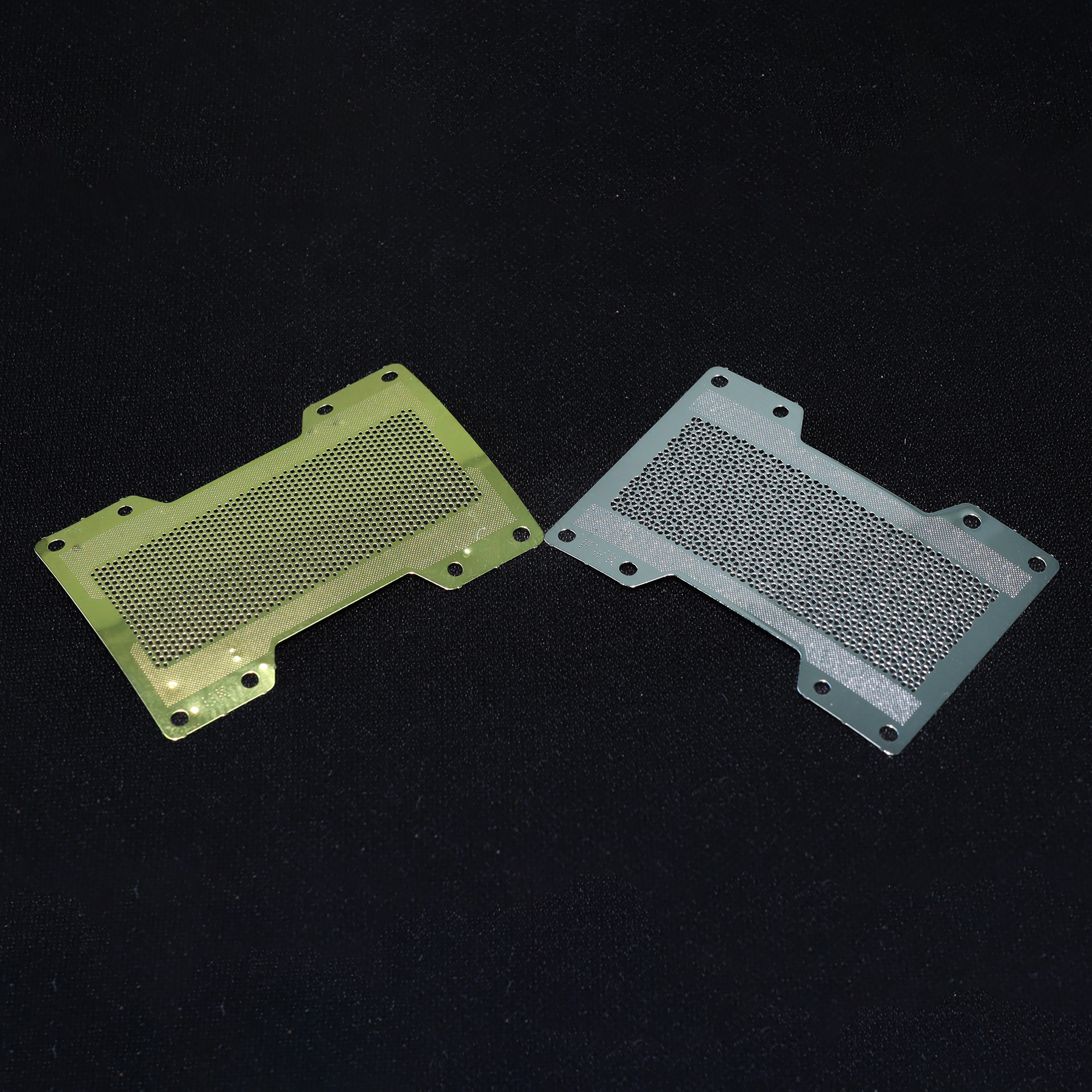

Electroforming technology can replicate the fine structure of molds, with high precision in the aperture, shape, and arrangement of shaver mesh. High precision mesh can effectively capture beard and provide a more comfortable shaving experience.

Complex structure

Electroforming technology can manufacture complex three-dimensional structures, and shaver nets can be designed in various shapes and patterns to meet different shaving needs.

Wide selection of materials

Electroforming can deposit various metal materials, such as nickel, chromium, copper, etc., to meet different performance requirements.

For example, nickel electroplated shaver mesh has good corrosion resistance and strength.

Surface smoothness

Electroforming technology can obtain products with high surface smoothness, and the surface of the shaver mesh is smooth, reducing irritation to the skin.

Good consistency

The electroplating process can ensure consistency in mass production, and the quality and performance of the shaver mesh are stable.