High conductivity

High conductivity metal materials such as copper, nickel, etc. are usually used to ensure good electrical connections and signal transmission

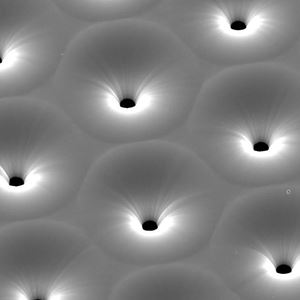

High elasticity

Electroforming technology can produce elastic pellets with high elasticity, ensuring good contact force and elastic recovery ability even after multiple uses

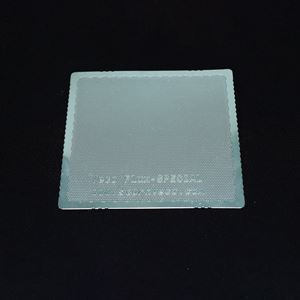

fine structure

Capable of producing very fine projectile structures, such as tiny contact points and complex geometric shapes, to accommodate different types of IC pins

durability

Due to the high strength of the material and the high consistency of the electroplating process, electroplated SOCKET test pellets usually have a long service life and can withstand high-frequency insertion and extraction operations

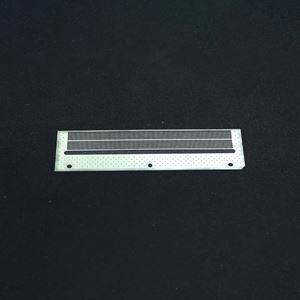

Semiconductor testing

Widely used for various types of IC testing, including logic chips, memory chips, microprocessors, etc.

Suitable for chips with different packaging forms, such as BGA, QFN, LGA, etc.

High frequency applications

In the testing of high-frequency communication chips, electroplated SOCKET test pads can provide low impedance connections, reduce signal loss, and ensure signal integrity.

Precision electronic component testing

Suitable for functional testing, aging testing, environmental testing, etc. of precision electronic components.

high-precision

Electroforming technology can process at the nanoscale, producing extremely fine structures suitable for high-precision applications

Complex structure

Capable of producing complex geometric shapes and fine features that are difficult to achieve with traditional processes, such as micropores, filaments, etc

High consistency

Electroforming technology can ensure the consistency of each projectile, reduce variability in the production process, and improve product quality

Diverse material selection

Different metal materials can be selected as needed, such as nickel, cobalt, copper, etc., to meet different mechanical and electrical performance requirements

Electroformed SOCKET test pellets have significant advantages in electronic component testing, especially in applications that require high precision, high reliability, and complex structures. Its high conductivity, high elasticity, and fine structure make it an ideal choice for precision testing. If you have specific application requirements or need further assistance, please feel free to let me know!