High precision and high resolution

Electroforming technology can manufacture high-precision and high-resolution apertures, improving the performance of optical systems.

high reflectivity

Using high reflectivity metal materials to enhance the reflection and control of light beams by the aperture.

Durability and stability

Electroformed aperture plates have high mechanical strength and chemical stability, as well as wear resistance and corrosion resistance.

Large area and complex structure

Electroforming technology can manufacture large-area and complex structured apertures to meet different application requirements.

Microscope

Used to control the shape and size of the illumination beam, improve imaging quality and resolution.

telescope

Used to limit the size of the beam entering the telescope, improve imaging clarity and contrast.

Laser

Used to control the shape and direction of the laser beam, improve the output power and beam quality of the laser.

Optical measuring instruments

Used to control the size and shape of the light beam, improve measurement accuracy and resolution.

Research and Development

Used for various scientific research experiments and development projects, as precision optical components for optical measurement and experimentation.

Electroformed aperture plate is a precision optical component that combines the advantages of electroplating technology with the functional requirements of aperture, and has the advantages of high precision, high reflectivity, durability, and complex structure. Electroformed aperture plates are widely used in optical instruments such as microscopes, telescopes, and lasers, providing high-performance optical components for various optical applications.

high-precision

Electroforming technology can replicate the fine structure of molds, with high precision in the shape, size, and aperture of the aperture.

High precision apertures can precisely control the shape and size of light beams, improving the performance of optical systems.

high reflectivity

Electroformed aperture plates typically use high reflectivity metal materials such as gold, silver, aluminum, etc.

A high reflectivity aperture can effectively reflect and restrict light beams, improving the efficiency and signal-to-noise ratio of optical systems.

durability

Electroformed aperture plates have high mechanical strength and chemical stability, as well as wear resistance and corrosion resistance.

A durable aperture can extend the service life of optical instruments.

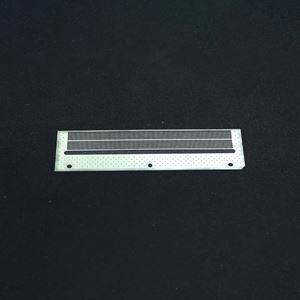

Large scale processing

Electroforming technology can manufacture large-area apertures, suitable for applications that require large-area apertures.

Complex structure

Electroforming technology can manufacture complex three-dimensional aperture structures to meet the needs of different optical applications.

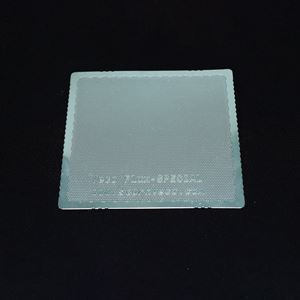

circular iris

Used to control the diameter and shape of light beams, commonly used in optical instruments such as microscopes and telescopes.

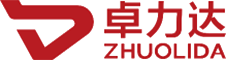

Square aperture

Used to control the cross-sectional shape of a beam, commonly used in lasers, optical measuring instruments, etc.

Adjustable aperture

By adjusting the aperture size of the diaphragm through a mechanical device, dynamic control of the beam size can be achieved.

Porous aperture

A diaphragm with multiple apertures used in multi beam optical systems.