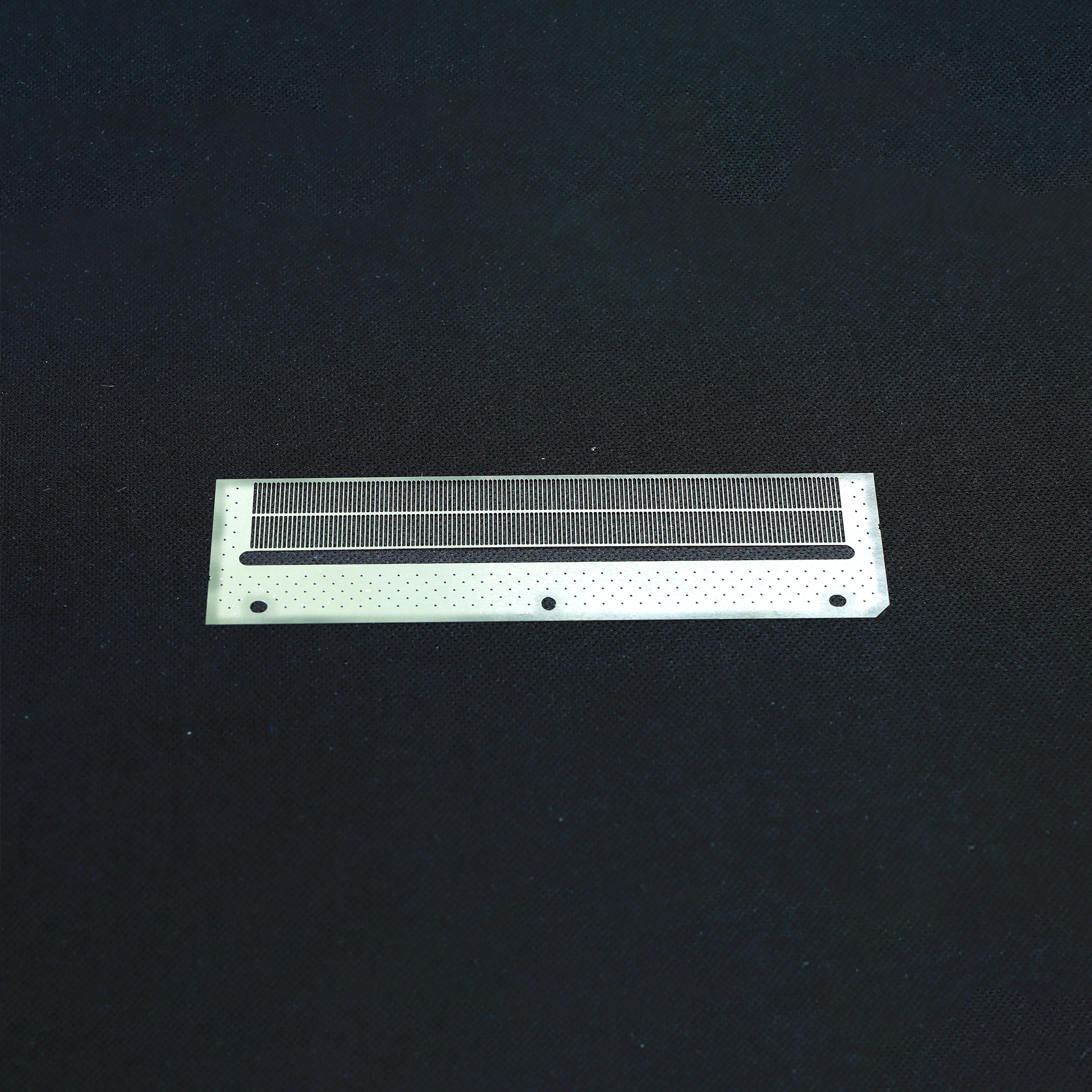

High precision and high resolution

Electroforming technology can manufacture high-precision and high-resolution gratings, improving the performance of optical systems.

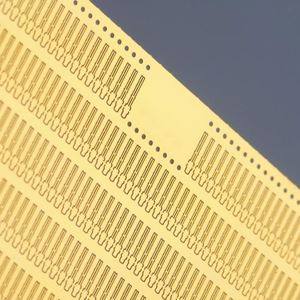

high reflectivity

Using high reflectivity metal materials to improve the reflection and diffraction efficiency of gratings.

Durability and stability

Electroformed gratings have high mechanical strength and chemical stability, as well as wear resistance and corrosion resistance.

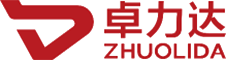

Large area and complex structure

Electroforming technology can manufacture large-area and complex structured gratings to meet different application requirements.

spectral analysis

Electroformed gratings are widely used in spectral analysis instruments such as spectrometers and spectrophotometers for spectroscopy and wavelength selection.

Laser technology

Electroformed gratings are used in lasers and laser processing equipment as grating elements for beam control, mode selection, and wavelength tuning.

optical instrument

Electroformed gratings are used as key optical components in microscopes, telescopes, optical measuring instruments, etc.

Communication and Information Processing

Electroformed gratings are used in fields such as fiber optic communication and optical information processing, as grating filters, grating couplers, etc.

Research and Development

Electroformed gratings are used in various scientific research experiments and development projects as precision optical components for optical measurement and experimentation.

high-precision

Electroforming technology can replicate the fine structure of molds, with high precision in the period, depth, and shape of gratings.

High precision grating structures can improve the diffraction efficiency and resolution of optical components.

high reflectivity

Electroformed gratings typically use high reflectivity metal materials such as gold, silver, aluminum, etc.

High reflectivity gratings can effectively reflect and diffract light, improving the performance of optical systems.

durability

Electroformed gratings have high mechanical strength and chemical stability, as well as wear resistance and corrosion resistance.

Durable gratings can extend the lifespan of optical instruments.

Large scale processing

Electroforming technology can manufacture large-area gratings, suitable for applications that require large-area gratings.

Complex structure

Electroforming technology can manufacture complex three-dimensional grating structures to meet the needs of different optical applications.

Electroformed grating is a precision optical component that combines the advantages of electroplating technology with the functional requirements of gratings. It has the advantages of high precision, high reflectivity, durability, and complex structure. Electroformed gratings are widely used in fields such as spectral analysis, laser technology, and optical instruments, providing high-performance optical components for various optical applications