Metal reflective encoder is a precision optical component manufactured using electroplating technology, widely used in encoders, optical measuring instruments, and precision positioning systems. The reflective encoder utilizes the principles of light reflection and diffraction to achieve precise angle or position measurement by depositing fine gratings or engraved line structures on a metal substrate.

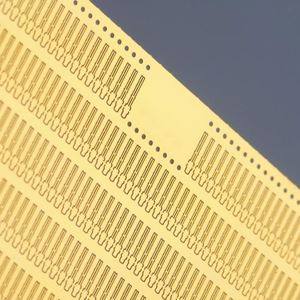

Code disk structure

The surface of the code wheel is engraved with fine gratings or engraved lines, which can be circular, spiral, or other geometric shapes.

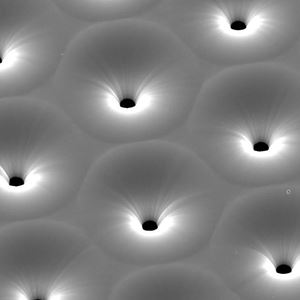

Reflection and diffraction

When light shines on the surface of the encoder, the grating or engraved line structure reflects and diffracts the light, forming a specific optical signal.

signal detection

By detecting reflected or diffracted light signals through photodetectors, angles, positions, or velocities can be accurately measured.

High precision and high resolution

Electroforming technology can manufacture high-precision and high-resolution code disks, improving measurement accuracy and resolution.

high reflectivity

Using high reflectivity metal materials to enhance the intensity and signal-to-noise ratio of optical signals.

Durability and stability

Electroformed metal reflective code discs have high mechanical strength and chemical stability, wear resistance, and corrosion resistance.

Large area and complex structure

Electroforming technology can manufacture large-area and complex structured code disks to meet different application needs.

encoder

Rotary encoder: used to measure the angle, velocity, or position of a rotating shaft, widely used in fields such as motor control, CNC machine tools, robots, etc.

Linear encoder: used to measure the position and velocity of linear motion, widely used in precision positioning systems, measuring instruments, etc.

Optical measuring instruments

Grating ruler: used for precision length measurement, such as coordinate measuring machines (CMM), laser interferometers, etc.

Angle encoder: used for precision angle measurement, such as angle measuring instruments, optical indexing heads, etc.

Precision positioning system

Used in applications that require high-precision positioning, such as semiconductor manufacturing, precision machining, and automated production lines.

Research and Development

Used for various scientific research experiments and development projects, as precision optical components for optical measurement and experimentation.

high-precision

Electroforming technology can replicate the fine structure of molds, and the grating or engraved lines of the encoder have high accuracy.

A high-precision encoder can improve measurement resolution and accuracy.

high reflectivity

Electroformed reflective code discs typically use high reflectivity metal materials such as gold, silver, aluminum, etc.

High reflectivity can improve the intensity and signal-to-noise ratio of optical signals.

durability

Electroformed metal reflective code discs have high mechanical strength and chemical stability, wear resistance, and corrosion resistance.

A durable encoder can extend the service life of the instrument.

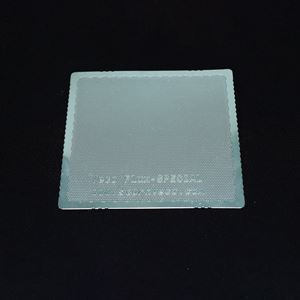

Large scale processing

Electroforming technology can manufacture large-area code discs, suitable for applications that require large-area code discs.

Complex structure

Electroforming technology can manufacture complex three-dimensional structures to meet the needs of different optical applications.

Electroformed metal reflective encoder is a precision optical component that combines the advantages of electroplating technology with the functional requirements of reflective encoder. It has the advantages of high precision, high reflectivity, durability, and complex structure. Electroformed metal reflective encoders are widely used in encoders, optical measuring instruments, precision positioning systems, and other fields, providing high-performance optical components for various optical applications.