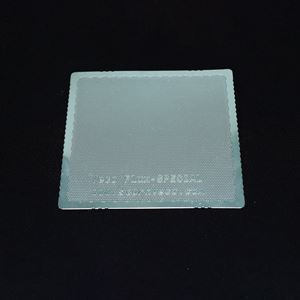

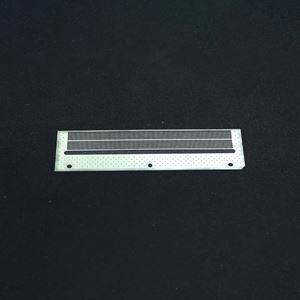

High precision micropores

Electroforming technology can replicate the fine microporous structure of molds, with high precision in the size, shape, and arrangement of micropores.

High precision micropores can precisely control the atomization effect and droplet size.

Uniformity

Electroforming technology can ensure the uniformity of micropores and ensure the stability and consistency of the atomization process.

High strength and durability

Electroformed atomization nets typically use high-strength metal materials such as stainless steel, nickel, chromium, etc.

The high-strength microporous structure can withstand significant pressure and wear, making it suitable for high-strength industrial applications.

Corrosion resistance

The metal materials used in electroformed atomization nets have good corrosion resistance, especially in medical and industrial applications, which can prevent material contamination of liquids or gases.

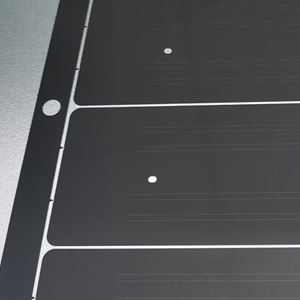

Complex structure

Electroforming technology can manufacture complex three-dimensional microporous structures to meet the needs of different atomization applications.

Medical Nebulizer

Used for medical nebulizers, dispersing drugs into tiny droplets for easy inhalation therapy by patients.

The high precision and corrosion resistance of microporous electroformed atomizing mesh make it an ideal choice for medical nebulizers.

Beauty spray

It is used as a beauty spray to disperse water or essence into tiny droplets and evenly spray them on the skin surface.

Microporous electroforming atomization net can provide delicate and even spray effect, and improve the beauty effect.

Industrial spraying

Used in industrial spraying equipment to disperse coatings, paints, etc. into tiny droplets and evenly spray them onto the surface of workpieces.

Micro porous electroformed atomizing mesh can improve spraying accuracy and uniformity, and reduce coating waste.

Humidifier

Used for humidifiers to disperse water into tiny droplets and increase air humidity.

Micro porous electroplated atomizing mesh can provide delicate and uniform humidification effect, improving air quality.

Other applications

Suitable for other occasions that require atomization or aerosol gelation, such as laboratories, environmental protection, agricultural spraying, etc.

High precision atomization

High precision micropores can precisely control the atomization effect and droplet size, improving atomization accuracy.

Uniformity

The uniformity of micropores ensures the stability and consistency of the atomization process.

Strong durability

High strength metal materials and corrosion resistance give it a longer service life.

sanitary

Electroformed atomization is suitable for cleaning and disinfection, meeting the hygiene standards of the medical and food industries.

Design flexibility

Electroforming technology can achieve complex designs and structures, meeting the special needs of different products and applications.

After post-processing, improve the surface quality and performance of the atomization net.

Micro porous electroformed atomizing mesh is a precision atomizing component that combines the advantages of electroforming technology with the functional requirements of atomizing mesh. It has the advantages of high precision, high strength, corrosion resistance, and uniformity. Micro porous electroformed atomization mesh is widely used in medical, beauty, industrial spraying and other fields, providing high-performance solutions for various atomization applications.