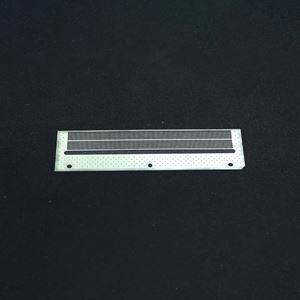

High precision aperture

Electroformed orifice plates can achieve extremely small aperture sizes, typically in the micrometer range, ensuring precise liquid or gas injection. The consistency and accuracy of aperture directly affect the uniformity and accuracy of injection.

High corrosion resistance

Electroformed orifice plates typically use corrosion-resistant metal materials such as nickel and stainless steel, which can be used in harsh environments such as high temperatures, high pressures, and corrosive liquids

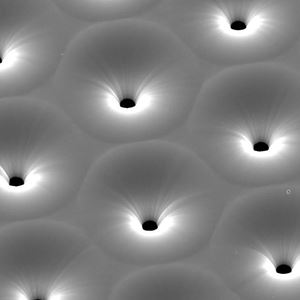

Complex hole shape

Electroforming technology can produce spray holes with complex shapes, such as conical holes, gradient holes, etc., to improve the efficiency and directionality of spraying.

Complex pore shapes can optimize the flow characteristics of liquids and reduce jet resistance.

High strength and durability

Electroformed spray orifice plates have high strength and durability, and can withstand high-frequency spray operations and high-pressure environments. Suitable for injection systems that require long-term reliable operation.

Inkjet printing

Widely used as a print head for inkjet printers, ensuring precise ejection and uniform distribution of ink droplets.

The high precision and consistency of electroplated orifice plates can significantly improve printing quality and resolution.

Fuel injection

Fuel injectors used in automotive and aviation engines ensure precise fuel injection and combustion efficiency.

The high corrosion resistance and strength of electroplated orifice plates can meet the high temperature and high pressure environment of engines.

Liquid distribution

Applied to systems that require precise control of liquid distribution, such as medical equipment and chemical analysis instruments.

The high precision and reliability of electroplated orifice plates can ensure the accuracy and consistency of liquid distribution.

Microfluidics

Applied to microfluidic chips and biochips, ensuring precise control and distribution of liquids.

The high precision and complex structure of electroplated orifice plates can meet the complex requirements of microfluidic systems.

high-precision

Electroforming technology can process at the micrometer or even nanometer level, producing extremely fine pore structures and geometric shapes.

Suitable for applications that require high-precision jetting, such as inkjet printing and precision liquid dispensing.

Complex structure

Electroforming can produce complex geometric shapes and fine features that are difficult to achieve through traditional mechanical processing, such as micropores, filaments, complex surfaces, etc.

Suitable for nozzle plate designs that require special hole shapes and structures to improve the efficiency and accuracy of spraying.

High consistency

Electroforming technology can ensure the consistency of each nozzle, reduce variability in the production process, and improve product quality and reliability.

Suitable for mass production, ensuring consistent performance and size of each spray hole.

Diverse material selection

Different metal materials can be selected as needed, such as nickel, cobalt, copper, gold, etc., to meet different mechanical, electrical, and chemical performance requirements.

For example, nickel has good corrosion resistance and mechanical strength, and is commonly used in the manufacturing of spray orifice plates.

Electroformed spray orifice plates have significant advantages in precision spray systems, especially in applications that require high precision, high corrosion resistance, and complex structures. Its high-precision aperture, complex hole shape, and high strength make it an ideal choice for fields such as inkjet printing, fuel injection, and liquid distribution. If you have specific application requirements or need further assistance, please feel free to let me know!